Stud Welding Installation

Precision Stud Welding offers expert stud welding installation services following the highest design standards of quality and efficiency. Our team ensures that every stud is installed to meet the design requirements yielding structural integrity and longevity.

Explore our Services

Installation Details

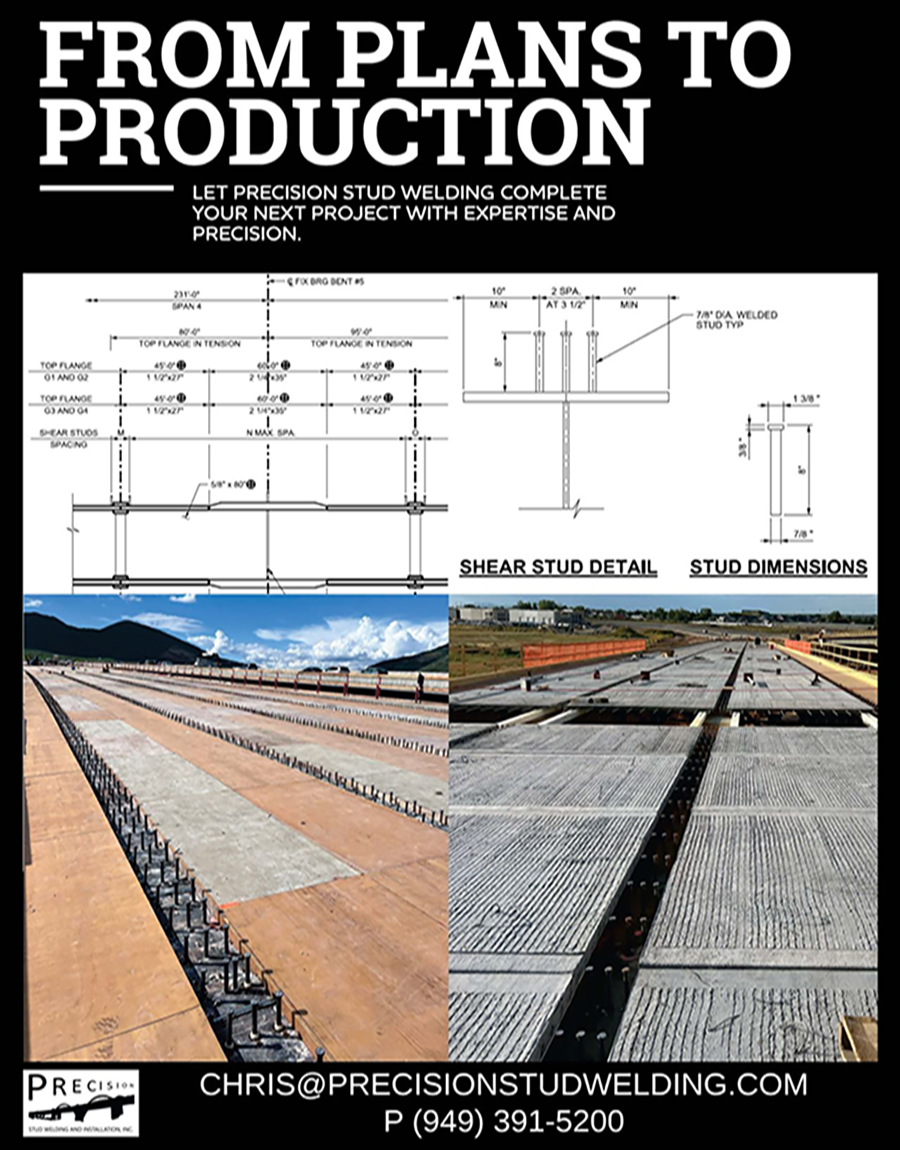

Stud welding installation is crucial in steel bridge construction for securing shear connectors and other vital components. This process involves attaching studs to metal surfaces, which are subsequently embedded in concrete to create a composite structure that enhances strength and durability. Our team employs traditional and advanced techniques to provide strong and reliable connections. By utilizing state-of-the-art equipment, we ensure precise and efficient installations that adhere to stringent project timelines and industry standards.

The application of stud welding in bridge construction offers significant advantages over traditional methods. One of the primary benefits is the creation of a composite structure, where the welded studs facilitate a robust connection between steel beams and concrete slabs. This method not only reduces labor costs and installation time but also results in stronger and more reliable connections. Our technicians are well-versed in various stud welding techniques, ensuring that each project meets specific engineering requirements and safety standards. The precision and reliability of our installations are critical for the long-term stability and performance of structures.

Quality control is a cornerstone of our stud welding installation process. When inspected the weld undergoes rigorous testing to ensure it meets both internal standards and industry regulations. By maintaining strict quality control protocols, we ensure that every stud weld contributes to the overall integrity of the structure. Our commitment to excellence extends beyond the installation phase, as we provide ongoing support and maintenance to ensure the long-term reliability of our work.

Explore our Safety Measures

Service Safety Measures

Pre-Task Checklist

Before initiating any stud welding installation on bridges, we conduct comprehensive pre-task checklists. These checklists ensure that all necessary equipment is inspected and ready for use, potential hazards are identified, and all safety gear is in place. This step helps to prevent accidents by addressing issues before work begins, ensuring a safe start to the project.

Task Hazard Analysis

For each specific task involved in stud welding on bridges, we perform detailed hazard analyses. This involves identifying potential risks such as electrical hazards, falls from height, and exposure to welding fumes. By analyzing these risks, we develop and implement strategies to mitigate them, such as using fall protection systems, ensuring proper ventilation, and utilizing personal protective equipment (PPE).

Weekly Safety Inspections

Regular safety inspections are conducted weekly to maintain high safety standards throughout the bridge construction project. These inspections involve checking the integrity of welding equipment, verifying that safety protocols are being followed, and ensuring that the work environment remains safe. Any issues identified during these inspections are promptly addressed to prevent accidents.

Safety Training Programs

Our safety training programs are designed to keep our welding teams up to date with the latest safety practices and regulations specific to bridge construction. Training includes proper equipment use, emergency response procedures, and safe welding practices. Continuous education ensures that our employees are well-prepared to handle the unique challenges of stud welding in bridge construction.

Emergency Preparedness Plan

We develop and regularly update emergency preparedness plans to ensure a quick and effective response to any incidents during bridge welding projects. These plans include protocols for dealing with accidents, such as welding burns or equipment failures, and ensure that all team members know their roles in an emergency. Regular drills and reviews of these plans help to keep everyone prepared for unexpected situations.

Contact Precision Stud Welding today for stud welding installation on your next bridge project.